PRODUCTS

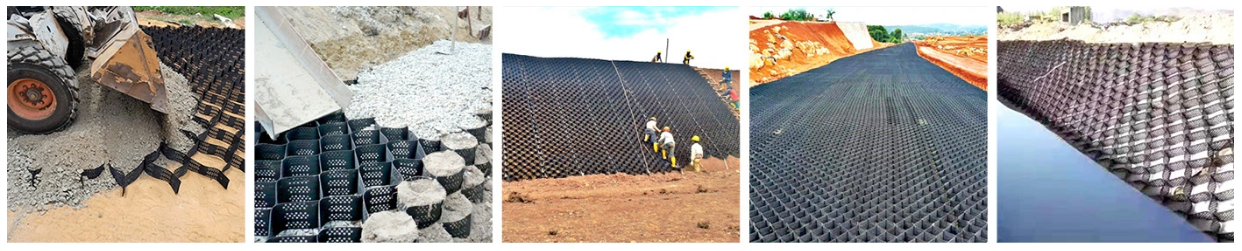

Application of geocells in river bank and river canal projects

Category:

HDPE Geocell

Keywords:

HDPE Geocell

Product Description

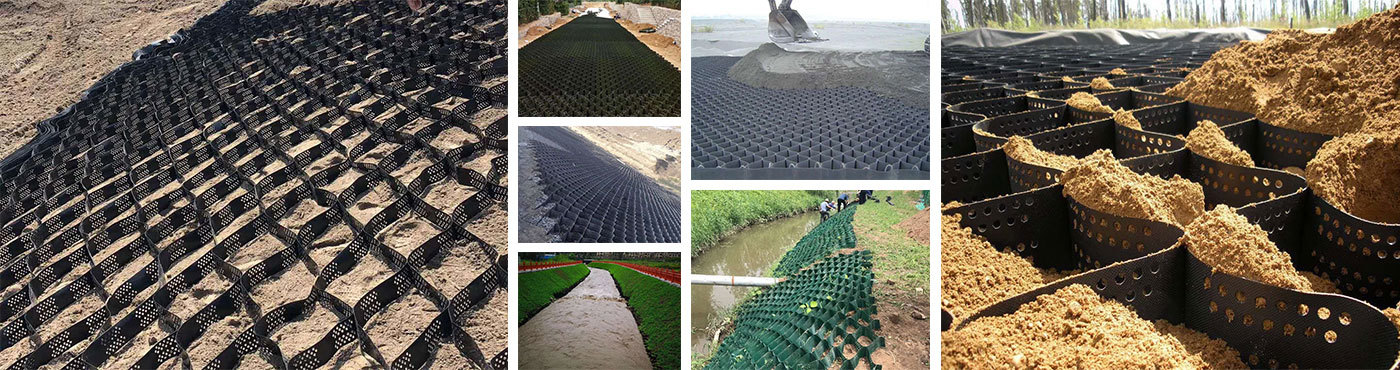

Geocell is a threedimensional honeycomb grid structure made of polymer materials such as highstrength polyethylene (HDPE) or polypropylene (PP), which is strongly welded or riveted. After unfolding, it forms a threedimensional grid cell, which can be filled with materials such as soil, sand, gravel and concrete. In the river bank and river canal project, geocells are mainly used for slope protection and bottom protection to prevent soil erosion, protect the stability of river banks and improve the water ecological environment.

Advantages

1. Prevent soil erosion: Effectively restrain the soil body, prevent scouring by water flow, and reduce the erosion of riverbanks and canals.

2. Improve stability: Enhance the overall stability of riverbanks and canals to prevent landslides, subsidence and other disasters.

3. Strong adaptability: According to different hydrological conditions and topography and geomorphology, the appropriate size of the chamber and filler can be selected to adapt to a variety of complex environments.

4. Ecofriendly: It can be filled with local soil or planted with vegetation to realize ecological slope protection and improve the water ecological environment.

5. Simple and fast construction: light weight, easy to transport and install, can greatly shorten the construction period, reduce project costs.

6. Good durability: using high quality polymer materials, with excellent antiaging, corrosion resistance, long service life.

7. Good economy: Compared with the traditional concrete slope, the cost is lower and the maintenance cost is less.

Specification

| Material Composition | 0.935-0.965g/cm3 | ASTM D1505 | ||

| Color | Black/Gray/Green or Customized | N/A | ||

| Strip Properties | ||||

| Sheet Thickness | Before Textured:≥1.0/1.1/1.2mm or customized | ASTM D5199 | ||

| Cell&Seam Properties | ||||

| Cell Details | Welding distance (mm) | Dimension of per cell after expanded(±3%) | Expanded Panel size(Customization) | |

| Length(mm) | Width(mm) | |||

| GC-330 | 330 | 249 | 215 | 4.5m x 5.6m |

| GC-356 | 356 | 268 | 231 | 5.1m x 5.9m |

| GC-445 | 445 | 335 | 290 | 4.9m x7.1m |

| GC-660 | 660 | 486 | 420 | 5.0m x 9.5m |

| Cell depths(±2%) | 100mm,150mm,200mm,250mm,or customized | |||

| Welding Seam Peel Strength(±3%) | Can customized producing according the project condition. | |||

| 14.2KN/m | ISO 10319 | |||

| 16.0KN/m | ||||

| 18.0KN/m | ||||

| 20.0KN/m | ||||

| Geocell sheet Tensile Strength(±5%) | Non-perforated: >20 / 24 kn/m | ISO 10319 | ||

| Perforated:>10 / 15 kn/m | ||||

| Oxidative Induction Time (OIT) (±5%) | ≥ 20 / 100 Minutes | ASTM D5885 | ||

(A) Sheet thickness:

Common geocell sheet thickness of 1mm2mm, thinner sheet for water velocity is small, weak scouring force of the river channel; thicker sheet is used for rapid water flow, high protection requirements of the river bank project.

(B) Chamber height:

The height of the chamber is generally between 50mm 300mm. The smaller height of the chamber can be used for shallow protection and slope stabilization of small rivers and canals; the larger height of the chamber is suitable for deep protection, large river bank management and the need to fill more materials.

(C) Welding spacing:

Welding spacing is usually 330 1000mm, smaller welding spacing can make the geocell structure more compact, enhance the overall stability, suitable for high lateral constraint requirements of the region; larger welding spacing can reduce the cost, used for relatively low strength requirements of the part.

(D) Unfolding size:

The unfolded length of the geocell can be customized according to engineering requirements. Suitable unfolding size can be better adapted to the width and length of different canals and improve the construction efficiency.

Scenarios of use

1. River bank slope protection: used to protect the river bank, prevent water scouring, reduce soil erosion.

2. River channel bottom protection: used to protect the bottom of the river channel, prevent scouring, improve the stability of the river channel.

3. Ecological slope protection: combined with vegetation planting to realize ecological slope protection and improve the water ecological environment.

4. Reinforcement of dykes: Used to reinforce dykes and improve the flood resistance of dykes.

5. Reservoir slope protection: Used to protect reservoir slopes, prevent landslides and ensure reservoir safety.

6. Artificial wetland construction, ecological restoration: used to construct artificial wetland, purify water quality, improve the ecological environment.

River channel application mechanism

The application mechanism of geocells in riverbank canal project is mainly reflected in the following aspects:

1. constraining effect: geocell produces lateral constraints on the fill, restricts the shear deformation of the soil, and improves the shear strength of the soil.

2. dispersion of water impact: geogrid can disperse the impact of water flow, reduce the direct scouring of riverbanks and canals. 3. improve scour resistance: geogrid can disperse the impact of water flow, reduce the direct scouring of riverbanks and canals.

3. Improvement of scour resistance: Geocell and filler work together to form a whole protective layer, which improves the scour resistance of riverbanks and canals.

4. Promote the growth of vegetation: Geocell can provide a good growing environment for vegetation, promote the growth of vegetation, and further improve the effect of slope protection.

5. Improve the water ecological environment: the vegetation can absorb pollutants in the water, improve water quality, provide habitat for aquatic organisms and improve the water ecological environment.

Construction program

The construction of geocells in riparian canal projects generally includes the following steps:

1. site cleaning: clean up the construction site, remove debris, level the site.

2. Slope trimming: trim the slope of river bank or river channel to meet the design requirements. .

3. geotextile laying (optional): lay a layer of geotextile on the slope surface for isolation and drainage..

4. Geocell Laying: Spreading out the geocells and connecting the adjacent cells to form a continuous protective layer.

5. Anchoring: Use anchors or Unails to secure the geocells to the slope surface to prevent sliding.

6. Filling: Fill the selected filling material into the cell in layers, the thickness of each layer should not exceed 30cm, and compaction.

7. Vegetation planting (optional): Plant vegetation on the surface of the fill to realize ecological slope protection.

8. Drainage facilities: Set up necessary drainage facilities to eliminate water on the slope.

Construction Precautions

The laying direction of geocell should be parallel or perpendicular to the water flow direction.

The filling material should be gravel soil or gravel soil with good grading and no debris.

Avoid damaging the geocell during filling.

During compaction, the degree of compaction and water content should be controlled to ensure that the fill is dense.

The anchoring should be firm and reliable to prevent the soil from being damaged.

The anchoring should be firm and reliable to prevent the geocell from sliding.

Vegetation planting should be selected to adapt to local climate and soil conditions.

Drainage facilities should be unobstructed and regularly inspected and maintained.

An increasingly important application lies in promoting ecological restoration and vegetated solutions. When filled with topsoil and seeded, geocells provide an ideal matrix for plant root growth. The cells protect young vegetation from being washed away, anchor the root system, and facilitate the establishment of a durable green cover. This vegetated slope protection not only reinforces the soil through root reinforcement (bioengineering) but also improves habitat, water quality through filtration, and the overall aesthetic and ecological value of the watercourse, aligning engineering goals with environmental sustainability.

In summary, the application of geocells in riverbank and canal projects represents a significant advancement in geotechnical engineering. Their ability to provide robust erosion control, enhance slope stability, form flexible retaining structures, and support ecological restoration makes them a comprehensive solution for modern watercourse management. As the demand for resilient, cost-effective, and environmentally sensitive infrastructure grows, the role of geocell technology in protecting and stabilizing our vital waterways is set to become even more prominent and indispensable.

Case Display

15+ Experience In Geosynthetics&Experts In Slope Protection, Landscaping And Soil Stabilization Solutions.

Boyuan Geosynthetics provides perfect environmental protection slope protection, greening and soil stabilization system solutions for global customers in large-scale civil engineering projects such as highway and railroad transportation, water conservancy construction, landscaping, bridges and tunnels.

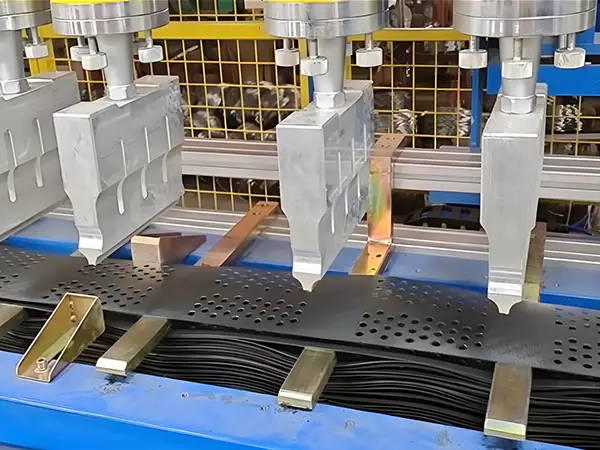

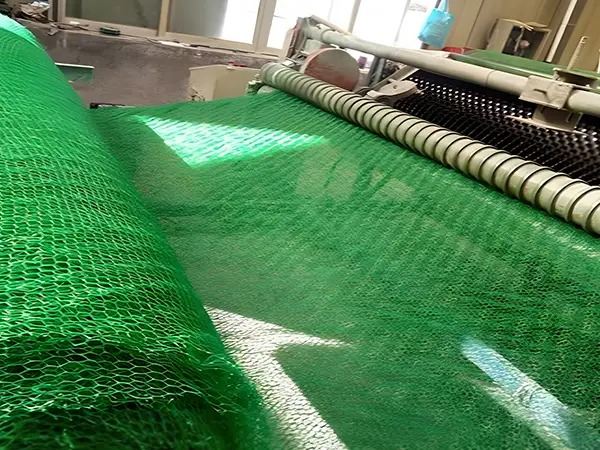

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

Geomat Production Lines

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE