PRODUCTS

Factory Price 100g 200g 300g Non Woven Polyester Needle Punched Fabric Geotextile

Category:

Non-Woven PP Geotextile

Keywords:

Non-Woven PP Geotextile

Product Description

Anti-seepage non-woven geotextile is a high quality fabric that is designed to prevent seepage of water or other liquids. It is commonly used in civil engineering projects such as road construction, landfill liners, and erosion control.

The non-woven geotextile is made from synthetic fibers that are needle-punched together to create a strong and durable fabric. This fabric is then treated with special coatings to make it resistant to water and chemicals.

The anti-seepage non-woven geotextile is easy to install and provides excellent protection against water seepage. Its high tensile strength and puncture resistance make it an ideal choice for applications where water seepage is a concern.

Overall, the anti-seepage non-woven geotextile is a versatile and reliable solution for preventing water seepage in a variety of civil engineering projects. Its durability, ease of installation, and effectiveness make it a popular choice among engineers and contractors.

|

|

|

|

|

Non-woven geotextile, also known as non-woven geotextile fabric, is a permeable geosynthetic material made from polyester or polypropylene fibers. It is widely used in various civil engineering and environmental projects due to its excellent filtration, drainage, and separation properties.

One of the main applications of non-woven geotextiles is in the construction of roads and highways. They are often used as a separation layer between the subgrade and base courses to prevent the mixing of different soil layers and improve the overall stability and performance of the pavement. Non-woven geotextiles also help to reduce the potential for rutting and cracking by providing a stable and uniform base for the road surface.

In addition to road construction, non-woven geotextiles are also commonly used in environmental protection projects such as landfill liners and caps. The high tensile strength and puncture resistance of these geotextiles make them ideal for preventing the leakage of contaminants from landfills into the surrounding soil and groundwater. They can also be used in erosion control applications to stabilize slopes and prevent soil erosion in sensitive environmental areas.

Non-woven geotextiles are also used in various drainage applications, such as in retaining walls, landfills, and drainage ditches. By allowing water to pass through while retaining soil particles, these geotextiles help to prevent clogging and maintain the efficiency of the drainage system. They are also commonly used in subsurface drainage systems to collect and redirect excess water away from structures and foundations.

Overall, the applications of non-woven geotextiles are diverse and extensive, making them a versatile and cost-effective solution for a wide range of civil engineering and environmental projects. Their durability, flexibility, and high performance make them a popular choice for engineers and contractors looking to enhance the functionality and longevity of their projects.

Product parameters

| Properties | Test Method | Unit | GXSF150 | GXSF200 | GXSF300 | GXSF400 | GXSF500 | GXSF600 | GXSF800 | GXSF1000 |

| Tensile Strength(MD/TD) | ASTM D4595 | kN/m | 8 | 11 | 20 | 24 | 28 | 34 | 48 | 50 |

| Tensile Elongation(MD/TD) | ASTM D4595 | % | 50 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Grab Tensile Strength(MD/TD) | ASTM D4632 | N | 520 | 700 | 1100 | 1500 | 1800 | 2200 | 2800 | 3000 |

| Grab Elongation(MD/TD) | ASTM D4632 | % | 50 | 50 | 60 | 60 | 60 | 60 | 60 | 60 |

| Trapezoidal Tear Strength(MD/TD) | ASTM D4533 | N | 220 | 330 | 400 | 480 | 560 | 620 | 860 | 880< |

Case Display.

15+ Experience In Geosynthetics&Experts In Slope Protection, Landscaping And Soil Stabilization Solutions.

Boyuan Geosynthetics provides perfect environmental protection slope protection, greening and soil stabilization system solutions for global customers in large-scale civil engineering projects such as highway and railroad transportation, water conservancy construction, landscaping, bridges and tunnels.

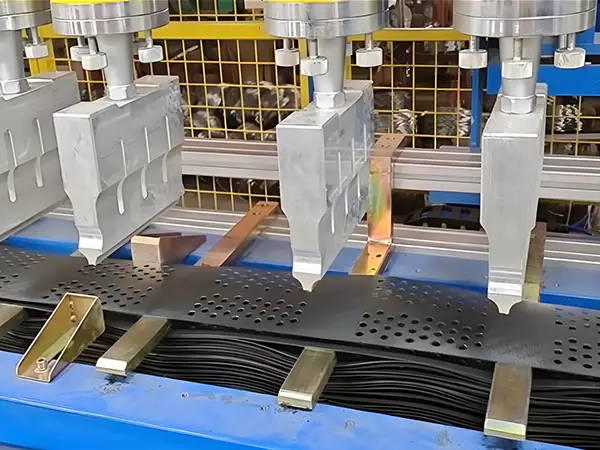

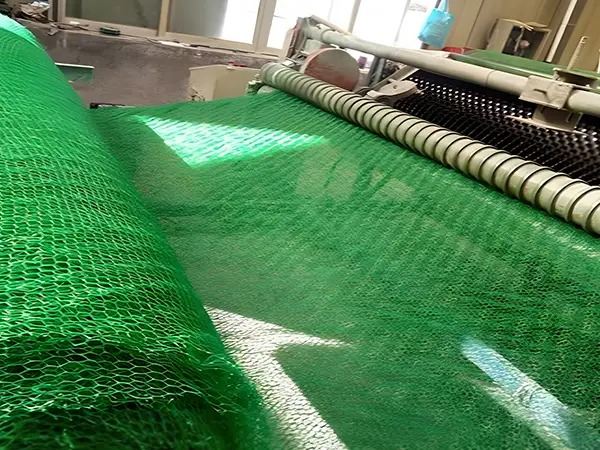

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

Geomat Production Lines

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE