PRODUCTS

Filtration-Drainage Tri-Dimensional Composite Geonets

Category:

Geocomposite

Keywords:

Geocomposite

Product Description

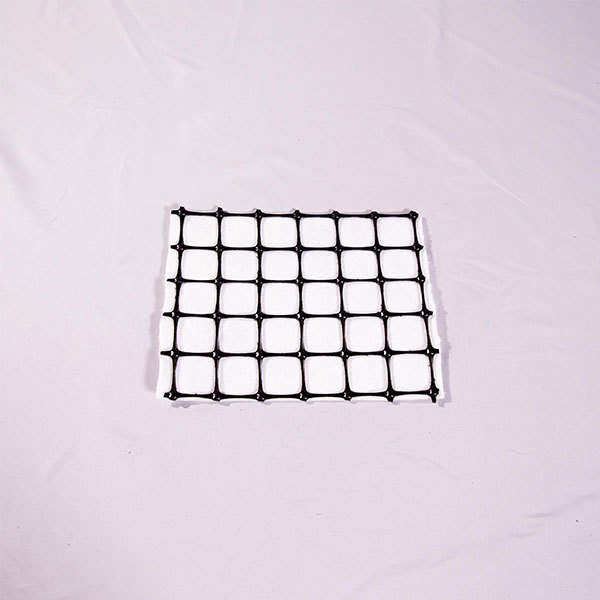

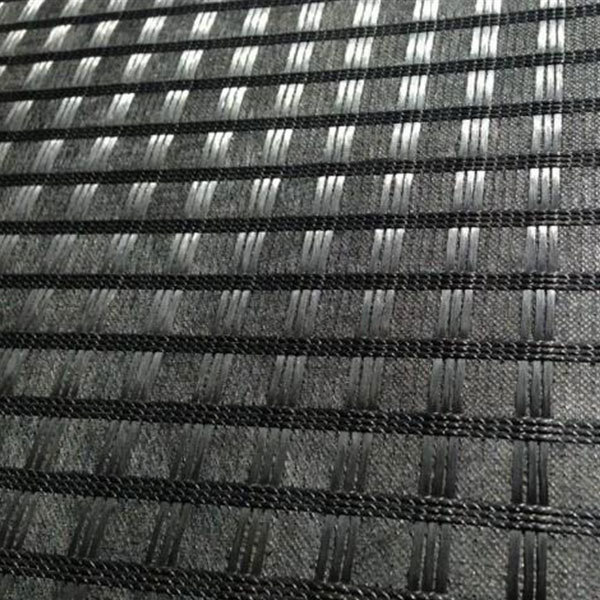

Fiberglass Geogrid Composite with nonwoven fabric is an asphalt reinforcement composite that fiberglass geogrid with nonwoven Fabric. They are composited together by pressure sensitive glue. The chemistry stability is good, the hot-stability is good, anti-weary dehiscence, anti-low temperature shrinkage crack, postponement reduction reflection crack. The nonwoven simplifies installation and ensures continuous bond between the layers. This excellent adhesion allows Geocomposite to take up and evenly distribute tensile forces.

Composite geogrids: 25*25KN, 30*30KN, 40*40KN, 50*50KN, 60*60KN, 80*80KN, 100*100KN, 120*120KN

Nonwoven fabric: 80g/ 100g/ 200g

Customized as per your requirements.

Performance Indicators

| Specifcation | WTF 30-30 | WTF 50-50 | WTF 80-80 | WTF 100-100 | WTF 120-120 | WTF 150-150 | WTF 200-200 | WTF 300-300 | |

| Mesh size(mm) | 25.4×25.4 or 12.5×12.5 or 50.8×50.8 | ||||||||

| Breaking strength(kN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 | 150 | 200 | 300 |

| Across warp | 30 | 50 | 80 | 100 | 120 | 150 | 200 | 300 | |

| Elongation at break(%) | Warp direction | 4 | |||||||

| Across warp | 4 | ||||||||

| Thermal tolerance(C) | -100~280 | ||||||||

| Width≤(m) | 6 | ||||||||

Scope Of Application

■ Reinforcement of Pavement Asphalt layers, High way, Road surface, High trafficked area, Airport runway.

■ Anti-cracking reinforcement in asphalt

■ Overlays to old concrete roads

Construction Points

Storage Information:

•Store at temperatures above - 29°C (- 20°F).

•Storage location should be dry, preferably covered and free of dust, dirt and moisture.

•Do not allow excessive mud, fluid concrete, asphalt, or other deleterious materials to get in contact with the reinforcement mesh materials

•If stored outdoors, the rolls must be covered with proper water proof covering.

Surface Preparation:

•Pavement should be clean, dry and clear of all dust, dirt, and debris.

•Road surface temperature should be between 5 degrees C (40 degrees F) and 60 degrees (140 degrees F) and the surface temperature shall be between 5 degrees (40 degrees F) and 46 degrees C (110 degrees F) if the asphalt surface is less than 24 hours old.

•Seal cracks exceeding 6 mm (0.25 inch) in width using an approved sealant or the appropriate leveling course mix.

•Repair potholes and failed or cracked sections of pavements as instructed by engineer.

•Badly damaged or rough pavement may require milling or the placement of a leveling course.

Leveling Course Application:

•A minimum 0.75 in. (19 mm) thick asphalt concrete leveling course is required on milled surfaces or Portland Concrete pavements.

•A minimum 0.75 in. (19 mm) thick application is needed to provide sufficient adhesion.

Tack Coat Application:

•If a tack coat is specified, it may be applied before or after the installation of the Fiberglass geogrid GeoGeocomposite, depending on site conditions. Tack must be completely cured prior to paving. The use of tack-coat may further enhance adhesion and achieve strong bonding between the Fiberglass geogrid stitched with nonwoven fabric and asphalt layers.

•Apply tack coat uniformly over the prepared surface at a rate of 0.4 - .6kg/square meter / (0.39 -0.59 liters/square meter / 0.10 -0.15 gallons/square yard) using a calibrated distributor truck, ensuring that the application rate remains constant.

•It is recommended that only asphalt cement tack coats be used. For best results use the same asphalt cement that was used to make the HMA mix in the tack.

•Emulsified tack coats can be used but only when extreme caution is taken to make sure that the tack has properly broken. For best results use a rapid set tack coat such as a CRS-2. DO NOT use emulsified tack coats if any dust, dirt, or debris is present during time of application.

•New types of tack-less coats are available presently which have been tested by various agencies and seem to provide better shear strength when compared to CRS-1 and CRS-2.

•Any other types of tack coat must be pre-approved by a manufacturer representative.

Case Display.

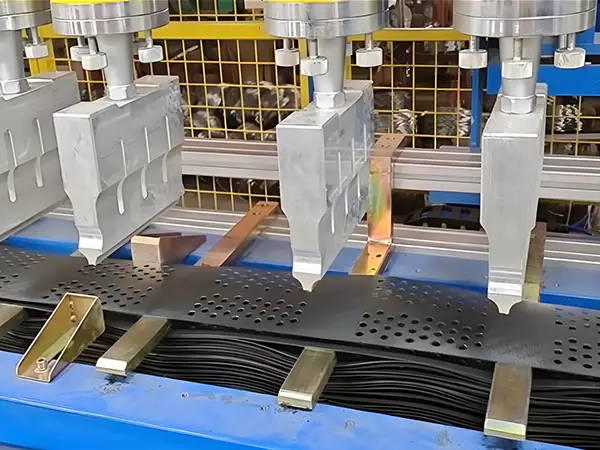

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

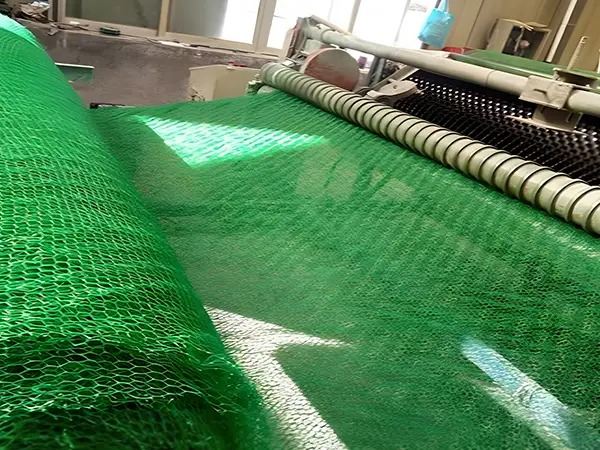

Geomat Production Lines

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE