PRODUCTS

Geotextile isolation and filtration engineering system solutions

Category:

Non-Woven PET Geotextile

Keywords:

Non-Woven PET Geotextile

Product Description

Geotextile is a kind of permeable geosynthetic material, which is made of synthetic fiber through needling, weaving or other processes. According to different manufacturing processes, it can be divided into needlepunched nonwoven geotextile and woven geotextile. In isolation project, geotextile is mainly used for isolation between different soil layers or different materials, preventing mixing, maintaining the performance of materials and improving the overall stability of the project.

Advantages

Excellent segregation performance: effectively prevent the mixing of different soil layers or materials, and maintain their respective properties.

Good water permeability: allows water to pass freely, while preventing the loss of soil particles and maintaining smooth drainage.

Enhanced soil stability: Improves the overall stability of the soil by isolating it and preventing settlement and deformation.

High tensile strength: It has high tensile strength and elongation, and can withstand certain tension and deformation.

Good corrosion resistance: able to resist the erosion of acids and alkalis and other chemicals, adapt to a variety of complex environments.

Construction is simple and fast: light weight, easy to cut and lay, can greatly shorten the construction period, reduce project costs.

Economic and environmental protection: can effectively use local materials, reduce the dependence on external resources, reduce carbon emissions.

Specification size

| Unit weight | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | NOTE |

| Items | ||||||||||||

| Tolerance/sqm (%) | -6 | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

| Thickness (mm)≧ | 0.8 | 1.3 | 1.6 | 2.1 | 2.2 | 2.5 | 2.8 | 3.3 | 3.4 | 4.2 | 5.5 | |

| Tolerance of width% | -0.5 | |||||||||||

| Tensile strength, KN/M | 5.5 | 8 | 10.5 | 13.5 | 16 | 20 | 22.5 | 25 | 28 | 33 | 45 | CD |

| MD | ||||||||||||

| Elongation at break ≦% | 35 | |||||||||||

| CBR bursting strength KN≧ | 0.8 | 1.5 | 2 | 2.8 | 3 | 3.5 | 4.1 | 4.8 | 5.5 | 6.5 | 8 | |

| Effective aperture 090(095) mm | 0.07-0.2 | |||||||||||

| Vertical permeability coefficient cm/s | Kx (10-4-10-3) | K=1.0-9.9 | ||||||||||

| Tearing strength KN≧ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.5 | 0.56 | 0.63 | 0.7 | 0.82 | 1.1 | CD |

| MD | ||||||||||||

Isolation filtration mechanism

It is mainly reflected in the following aspects:

1. Physical barrier: Geotextile can effectively block the direct contact between different soil layers or materials to prevent mixing.

Filtration: Geotextile has a certain porosity, allowing water to pass freely, while preventing the loss of soil particles, to maintain smooth drainage. Geotextile fiber structure also has a certain adsorption effect, can adsorb some of the fine impurities in the water and colloidal substances, to further improve the filtration effect.

2. Stress dispersion: geotextile can disperse the upper load, reduce the direct pressure on the lower soil layer, improve the overall stability of the soil body.

3. protection: geotextile can protect the lower soil layer from the scouring and erosion of the upper soil layer, prolonging the service life of the project.

Construction program

The construction of geotextile in isolation project generally includes the following steps:

1. site cleaning: clean up the construction site, remove debris, level the site.

2. geotextile cutting: according to the needs of the project, the geotextile will be cut into suitable size.

3. geotextile laying: lay the geotextile flat in the need to isolate the soil layer or between materials, lap width is generally 2030cm. 4. fixing: use Upegs to fix the geotextile.

4. Fixing: Use Ushaped nails, sandbags or other ways to fix the geotextile to prevent sliding.

5. Fill: lay fill on the geotextile and compact it.

6. quality inspection and acceptance: quality inspection should be carried out in time during the construction process to check whether the laying quality, splicing quality and fixing of geotextile meet the design requirements.

Construction precautions

The laying direction of geotextile should be consistent with the direction of the project.

The lap width of geotextile should be determined according to the needs of the project, generally not less than 20cm.

The fixing of geotextile should be firm and reliable to prevent sliding.

Damage to the geotextile should be avoided during the filling process.

Compaction should be controlled during compaction and water content to ensure that the filler is dense.

Attention should be paid to safety during construction to prevent accidents.

Case Display.

15+ Experience In Geosynthetics&Experts In Slope Protection, Landscaping And Soil Stabilization Solutions.

Boyuan Geosynthetics provides perfect environmental protection slope protection, greening and soil stabilization system solutions for global customers in large-scale civil engineering projects such as highway and railroad transportation, water conservancy construction, landscaping, bridges and tunnels.

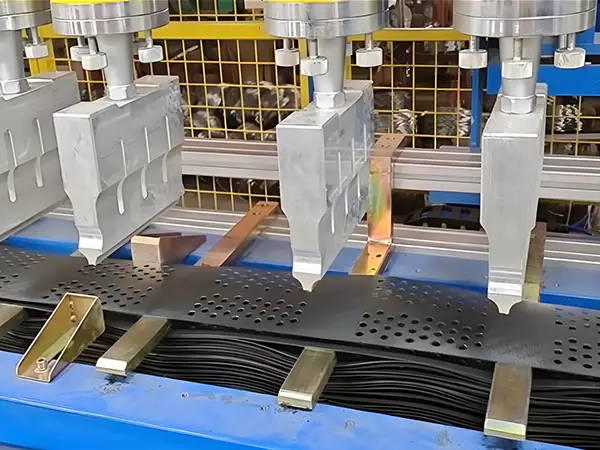

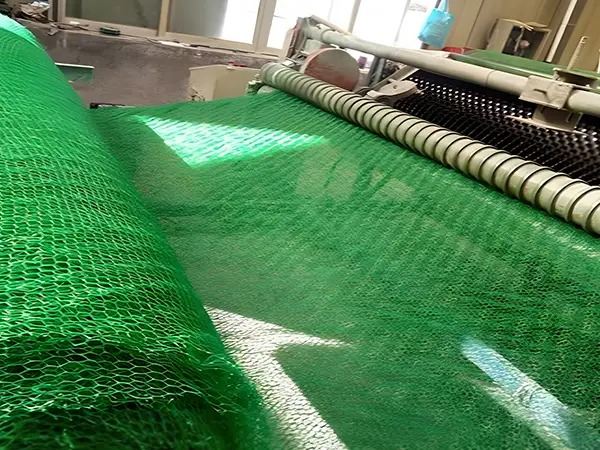

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

Geomat Production Lines

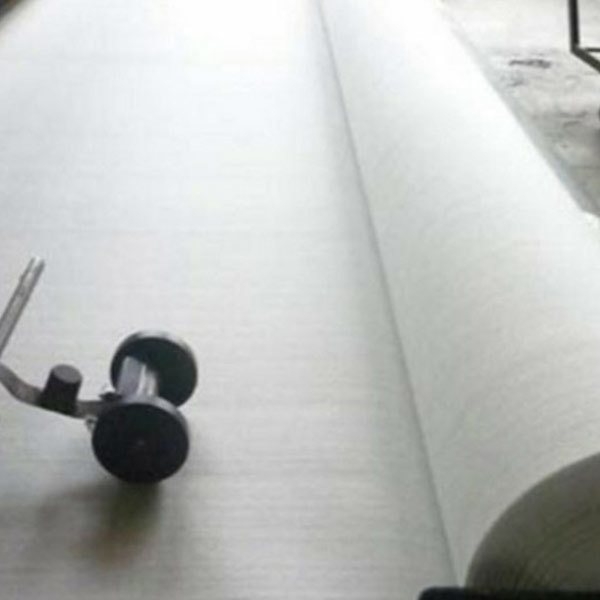

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE