PRODUCTS

Geotube Bags

Category:

Geo Bags

Keywords:

Geo Bags

Product Description

Product Concept

Geotubes (also known as geobags) are flexible, three-dimensional structures made of high-strength, durable geotextiles. They are filled hydraulically or mechanically with materials such as sand, silt, sludge, or concrete to create engineered structures with specific strength and stability. Geotubes offer advantages such as ease of construction, adaptability, environmental friendliness, and cost-effectiveness, making them widely used in coastal protection, riverbank stabilization, land reclamation, hydraulic engineering, and other applications.

Product Specifications

| Material | High-strength Polypropylene (PP) or Polyester (PET) geotextile |

| PP | Suitable for most freshwater and soil environments |

| PET | Suitable for high-strength requirements and marine environments |

| Weight | Typically ranges from 200g/m² to 1000g/m², customizable based on project requirements |

| Tensile Strength | Tested according to ASTM D4595/EN ISO 10319 standards,available in various strength grades |

| Circumference | 1m - 20m (Customizable) |

| Length | Customizable based on project requirements |

| Seaming Method | High-strength double-stitched seams or heat-welded seams |

| Filling Ports | Number and location customizable based on requirements |

| Color | Typically white, black, or gray, customizable |

Product Features

High Strength and Durability: Made of high-quality geotextiles with excellent tensile, tear, and UV resistance for long service life.

Good Permeability and Filtration: Allows water to flow freely while effectively retaining soil particles, preventing erosion.

Easy and Quick Installation: Requires no heavy equipment, can be quickly filled and installed, shortening construction time and reducing costs.

High Adaptability: Adaptable to various complex terrains and geological conditions, suitable for a wide range of engineering environments.

Environmentally Friendly and Economical: Utilizes locally available materials for filling, reducing transportation costs and minimizing environmental impact.

Design Flexibility: Customizable in size and shape to meet different design requirements.

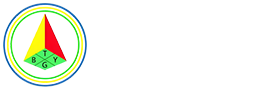

Application Areas

| Coastal Protection | Prevent coastal erosion and protect coastlines. |

| Riverbank Protection | Stabilize riverbanks and prevent soil erosion. |

| Land Reclamation | Used for land reclamation and expanding land area. |

| Hydraulic Engineering | Used for constructing dams, breakwaters, and other hydraulic structures. |

| Sediment Control | Used for sediment containment and dewatering in dredging projects. |

| Road and Railway Engineering | Used for roadbed reinforcement and slope stabilization. |

| Port and Wharf Engineering | Used for constructing wharves and breakwaters. |

Construction Process

1. Preparation:

Clear the construction site and level the ground.

Prepare Geotubes, filling equipment, connecting materials, etc.

Determine the placement and arrangement of Geotubes according to design requirements.

2. Filling:

Lay the Geotube flat in the designated position.

Fill the Geotube with sand, silt, or other materials hydraulically or mechanically.

Control the filling pressure and speed to ensure uniform filling of the Geotube.

3. Closing:

After filling, sew or weld the filling ports of the Geotube closed.

4. Stacking and Connecting:

Stack the Geotubes layer by layer according to design requirements.

Use connecting materials (such as geotextiles, ropes, etc.) to connect and fix the Geotubes, ensuring the stability of the overall structure.

5. Post-Construction Maintenance:

Regularly inspect the condition of the Geotubes and repair any damaged areas in a timely manner.

Clean debris from the surface of the Geotubes to maintain proper drainage.

Quality Control

We strictly follow international standards for production and quality control to ensure that every product meets customer requirements.

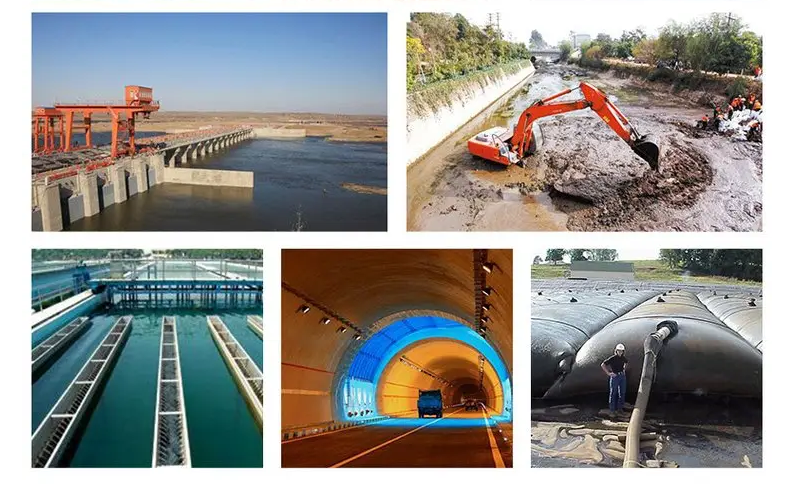

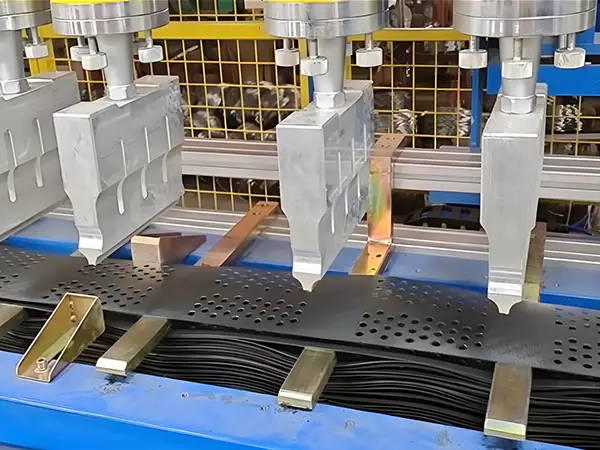

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

Geomat Production Lines

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE