PRODUCTS

White Needle Punched Polyester Non-Woven Geotextiles

Category:

Non-Woven PET Geotextile

Keywords:

Non-Woven PET Geotextile

Product Description

Polyester filament geotextile is a material made directly by spinning, needle punching, and consolidation using polyester method, which has excellent heat and light resistance properties.

Material: PET/PP

Width: 1-6M

Weight: 100-800 g/m2

Thickness: 1.0-5.0 mm

Customization: Various specifications can be processed and customized according to customer requirements

Function

1. Filtration

2. Underground drainage

3. Road separation/railway stability

4. Geomembrane buffering

5. Reinforcement

6. Protection

Application

1. Road stability construction 2. Roof 3. Civil construction

4. Railway construction 5. Garbage landfill 6. Dam

7. Port and dock construction, etc

Performance Indicators

| Unit weight | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | NOTE |

| Items | ||||||||||||

| Tolerance/sqm (%) | -6 | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

| Thickness (mm)≧ | 0.8 | 1.3 | 1.6 | 2.1 | 2.2 | 2.5 | 2.8 | 3.3 | 3.4 | 4.2 | 5.5 | |

| Tolerance of width% | -0.5 | |||||||||||

| Tensile strength, KN/M | 5.5 | 8 | 10.5 | 13.5 | 16 | 20 | 22.5 | 25 | 28 | 33 | 45 | CD |

| MD | ||||||||||||

| Elongation at break ≦% | 35 | |||||||||||

| CBR bursting strength KN≧ | 0.8 | 1.5 | 2 | 2.8 | 3 | 3.5 | 4.1 | 4.8 | 5.5 | 6.5 | 8 | |

| Effective aperture 090(095) mm | 0.07-0.2 | |||||||||||

| Vertical permeability coefficient cm/s | Kx (10-4-10-3) | K=1.0-9.9 | ||||||||||

| Tearing strength KN≧ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.5 | 0.56 | 0.63 | 0.7 | 0.82 | 1.1 | CD |

| MD | ||||||||||||

Construction Introduction

1. Storage, transportation, and disposal of geotextiles

The geotextile roll should be protected from damage before installation and unfolding. Geotextile rolls should be stacked in a flat and waterlogged area, with a height of no more than four rolls and visible identification plates of the rolls. Geotextile rolls must be covered with opaque material to prevent UV aging. During storage, it is important to maintain the integrity of the labels and information.

During the transportation process (including on-site transportation from the material storage location to the work site), the geotextile roll must be protected from damage.

Geotextile rolls that have been physically damaged must be repaired. Geotextiles that are severely worn cannot be used. Any geotextile that comes into contact with leaked chemical reagents is not allowed to be used in this project.

2. Laying method of geotextile:

2.1 Manual rolling and paving; The fabric surface should be flat and have appropriate deformation allowance.

2.2 The installation of long or short wire geotextiles usually involves several methods such as overlap, stitching, and welding. The width of stitching and welding is generally above 0.1m, and the overlap width is generally above 0.2m. Geotextiles that may be exposed for a long time should be welded or sewn together.

2.3 Suturing of Geotextiles

All stitching must be continuous. Before overlapping, the geotextile must overlap by a minimum of 150mm. The minimum needle distance from the edge of the fabric (exposed edge of the material) should be at least 25mm.

Case Display.

15+ Experience In Geosynthetics&Experts In Slope Protection, Landscaping And Soil Stabilization Solutions.

Boyuan Geosynthetics provides perfect environmental protection slope protection, greening and soil stabilization system solutions for global customers in large-scale civil engineering projects such as highway and railroad transportation, water conservancy construction, landscaping, bridges and tunnels.

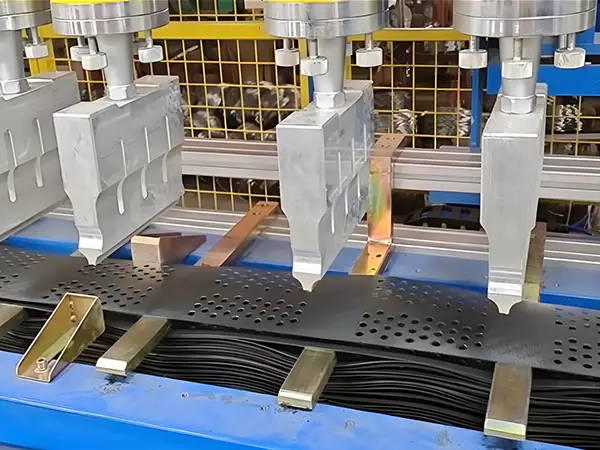

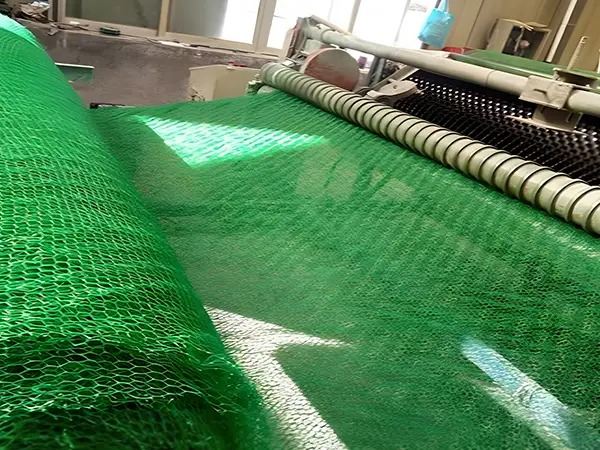

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

Geomat Production Lines

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE