PRODUCTS

HDPE Geocell

Category:

HDPE Geocell

Keywords:

HDPE Geocell

Product Description

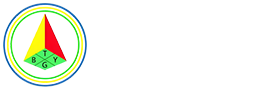

Structure: three-dimensional structure

Color: green, black, dark green

Height: 50-300mm (national standard/non-standard)

Welding distance: 300-1000mm

Material: Smooth embossed and perforated flat plate, non perforated

Sheet thickness: (flat smooth sheet) 1-1.2mm (embossed sheet) 1.3-1.5mm

Tensile yield strength: ≥ 20Mpa

Weld tensile strength: ≥ 100-142 (N/CM)

Customization:

Various specifications, height, welding distance, color, etc. can be processed and customized according to customer requirements

Function:

Environmental protection, slope protection, greening, road construction, soil consolidation, and foundation strengthening

To prevent the topsoil from sliding downwards, the permeable holes of the grid sheet can effectively seep through, reduce the gravity of the water body, and the vegetation roots in the grid are intertwined to form a strong anchoring force, effectively protecting the topsoil and resisting water erosion.

Geocell is a three-dimensional mesh cell structure formed by high-strength HDPE material and high-strength welding. It can expand and retract freely, can be folded during transportation, opened during use, and filled with materials such as sand, gravel, or soil in the cell, forming a structure with strong lateral limitations and high stiffness. It can be used as a cushion layer to enhance the bearing capacity of weak foundations, or laid on slopes to form slope protection structures. It can also be used to construct support structures, making construction convenient and fast.

Product Introduction

| Height (mm) | Weld Pitch (mm) | Sheet Thickness(mm) | Tensile Yield Strength ≥(Mpa) | Weld Tensile Strength ≥(N/CM) | |

| Thickness Of Flat Sheet Material | Thickness Of Embossed Sheet Material | ||||

| 50 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| 75 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| 100 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| 150 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| 200 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| 250 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| 300 | 300-1000 | 1-1.2 | 1.3-1.5 | 20 | 100-142 |

| Note: There are various specifications, and the product height, welding distance, color, etc. can be customized according to customer requirements. The punching of the cell is free, and accessories such as bolts are also included. | |||||

Slope Protection Mechanism

Geocell reinforcement of foundation is a mechanical soil reinforcement method that does not change the particle composition and interconnectivity of the filling material. Geogrids are mainly reinforced through interactions, which mainly include three aspects: the lateral constraint effect of the geogrid, the mesh effect of the geogrid, and the frictional effect of the geogrid.

The lateral constraint effect of the geocell is mainly reflected in two aspects: firstly, the frictional effect of the geocell on the soil outside the cell; The second is the clamping effect of the geocell on the soil within the grid element. The geotechnical cell provides a significant lateral constraint on the filling material, and the side walls of the cell generate upward frictional support force on the filling material, forming a composite with high flexural and tensile stiffness and shear strength. This complex can isolate the transmission of stress and displacement, thereby enabling flexible transition and coordinating the settlement of the top surface of the semi filled and semi excavated roadbed. Moreover, it has a net pocket effect on local loads, making the distribution of loads more uniform.

The frictional effect of the geocell is mainly reflected in the interface between the filler and the cell wall. The frictional force partially transfers the vertical load to the geocell, and then partially outward from the geocell. Through this transfer, the foundation pressure is reduced, thereby improving the bearing capacity of the cushion layer and reducing foundation settlement and uneven settlement.

The foremost advantage of the HDPE Geocell is its exceptional ability to provide three-dimensional confinement. Unlike planar geotextiles or geogrids, the cellular structure of the HDPE Geocell effectively locks the infill material in place, creating a composite layer that behaves as a semi-rigid slab. This system distributes loads over a much wider area, significantly increasing the bearing capacity of weak subgrades. This mechanism is fundamental for constructing roads, working platforms on soft soil, and railway embankments, where it prevents rutting and differential settlement. The three-dimensional reinforcement provided by the HDPE Geocell is a game-changer for construction on challenging ground.

Durability and longevity are inherent characteristics of the HDPE Geocell. High-Density Polyethylene is renowned for its excellent resistance to environmental stressors. It is impervious to biological degradation, resistant to a wide range of chemicals found in soils, and possesses outstanding toughness to withstand long-term ultraviolet radiation exposure. Furthermore, HDPE's high tensile strength and ductility allow the HDPE Geocell to absorb and distribute dynamic loads and stresses without brittle failure. This ensures that the structural integrity of the system is maintained for decades, making the HDPE Geocell a permanent solution for erosion control and load support applications.

Case Display

15+ Experience In Geosynthetics&Experts In Slope Protection, Landscaping And Soil Stabilization Solutions.

Boyuan Geosynthetics provides perfect environmental protection slope protection, greening and soil stabilization system solutions for global customers in large-scale civil engineering projects such as highway and railroad transportation, water conservancy construction, landscaping, bridges and tunnels.

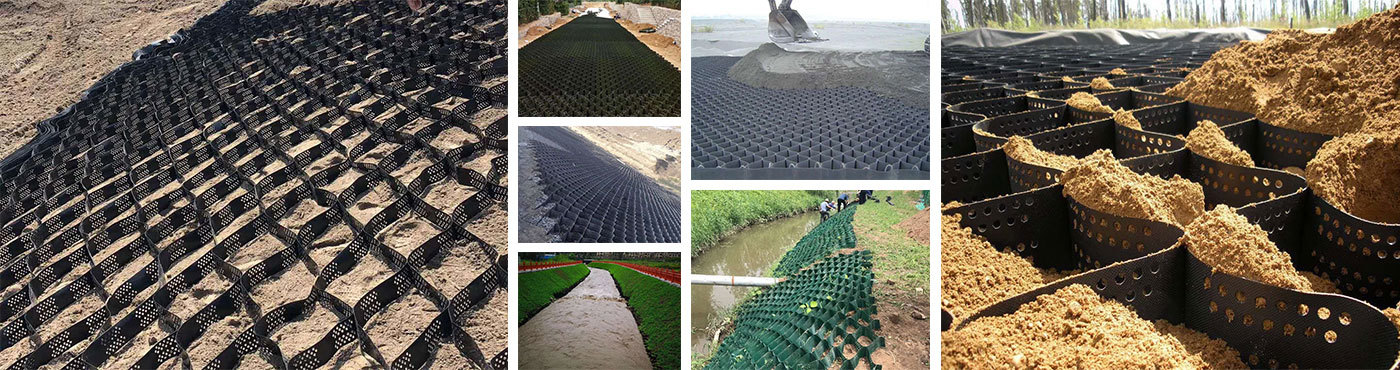

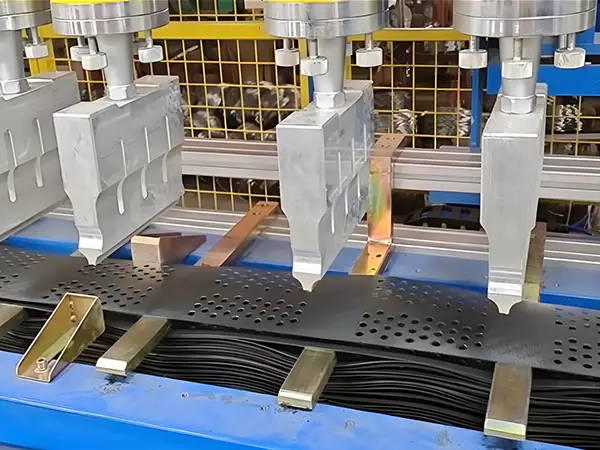

Production Facilities

We are a leading manufacturer of geosynthetics with a full range of production lines for geocells, erosion control nets, geotextiles, gabions geomembranes and geogrids. With a sizable annual production capacity and huge export volume, we utilize our core technologies and commitment to quality to provide reliable and efficient geotechnical engineering solutions to our customers worldwide.

We are committed to continuous improvement in production technology and full process product control to ensure excellence in every aspect of our products, from raw materials to finished products. Whether your needs are for small batch customization or large-scale production, our well-equipped system is capable of efficiently fulfilling the ever-changing product needs of the global geosynthetics market.

Geocell production lines

Geomat Production Lines

Geotextile production lines

Gabion Production Lines

Geogrid production lines

Geomembrane Production Lines

Testing Facilities

We always adhere to the principle of “Customer Satisfaction”, and strictly implement product quality standards, from raw material purchasing to finished products, we have established a perfect quality management system, and strictly control every link.

We are equipped with leading testing instruments and equipments, which can carry out all-round and accurate testing on the performance indexes of the products. We provide strong guarantee for product quality.

With strict quality control and advanced testing methods, we have successfully provided a large number of international customers with high-quality products and services, and won their trust and support.

Packaging and Transportation

Our products are packaged in waterproof and UV-resistant materials to protect them from the external environment during transportation.

All packaging is clearly labeled with product information and handling instructions to facilitate efficient customs clearance and delivery.

We offer a variety of packaging options, including palletized shipments, crate shipments and containerized shipments to meet specific customer requirements.

We offer a range of transportation options, including ocean, air and ground, to meet your specific delivery needs.

We work with experienced freight forwarders to ensure efficient customs clearance and timely delivery to your destination.

Our logistics team carefully monitors each shipment to ensure it arrives safely.

We provide comprehensive shipping documentation, including invoices, packing lists and certificates of origin for smooth import procedures.

Customer Testimonials

We are proud of the positive feedback we continue to receive from our international customers, which reflects our commitment to quality and customer satisfaction. We value the positive comments we receive from our international clients, which attest to our specialized industry knowledge.

We will continue to work hard to provide even better products and services to our customers. Customer satisfaction is our greatest motivation, and we will continue to adhere to our corporate development philosophy of innovation, excellence, cooperation and win-win situation to create greater value for our customers.

Customer visit

We are very pleased to receive international customers and fully introduce our products, services and production capacity to them.

We value the opportunity to build strong relationships with our international customers through site visits and cooperative discussions.

We are favored by both domestic and international customers for our superior quality and excellent service. Customers' visit is a confirmation of our strength and a source of motivation for us to keep moving forward. We will, as always, maintain long-term strategic cooperation with global customers to achieve win-win cooperation.

RELATED PRODUCTS

RELATED PRODUCTS

GET A FREE QUOTE